Welcome to HFW Solutions - The Leader In Friction Stir Welding Production Services

We are North America’s leading manufacturer of friction stir welded and CNC machined products. Our process-driven approach, coupled with top tier technology and expertise, allows HFW to lead the way in for excellence in production, engineering and quality.

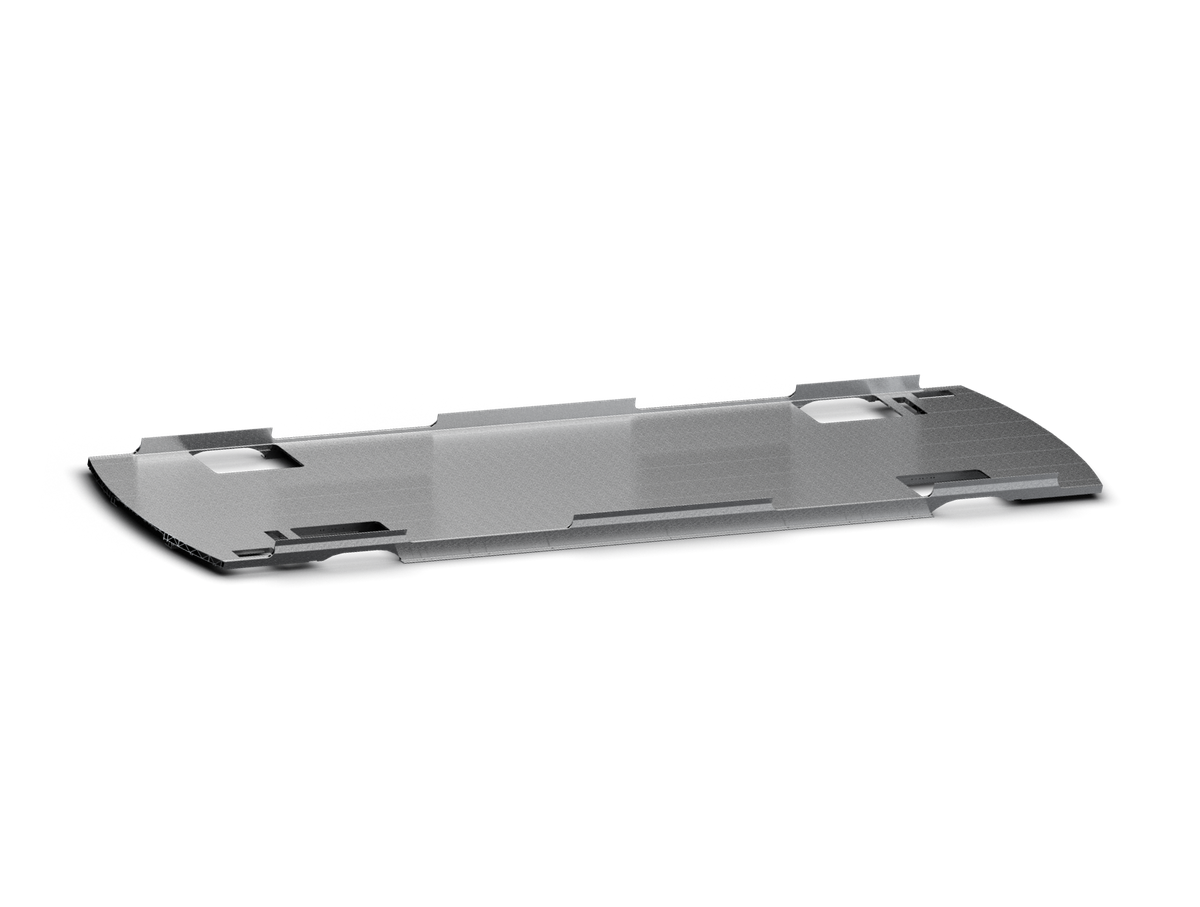

Are you looking for cold plates with unmatched performance and reliability?

- Leakproof. Never again worry about gasket and o-ring failure.

- Form factor. With FSW, no more fasteners are required for enclosing coolant circuits, reducing the overall envelope.

- Reliability. A unitized structure means our cold plates perform like they were made from one solid piece of metal.

Manufacturing

HFW has the capability to:

- Friction stir weld products

- Machine major assembly fabrications

- Aluminum fusion weld

- Fabricate extrusion based products

Engineering

HFW provides:

- Friction stir welding process

- Product/process qualification

- Aerospace/FAA experience

Certifications

HFW has the following certifications:

- AS9100

- American Bureau of Shipping (ABS)

- EN certified

- AWS D17.3

- American Welding Society (AWS)

Quality Management Systems

HFW is dedicated to quality:

- Process driven

- ISO/AS9100 compliant process

All Services

- From concept, design, and into volume production, we can assist you in all stages, becoming your all-around engineering, materials and fabrication resource.

- See all >

Featured Service

- Friction stir welding is a solid state joining process. HFW Solutions creates high quality, cost effective friction stir welded solutions.

- Learn more >

Contact HFW

Contact us today for a quote and to see what we can do for you.

- 1-605-343-3260

- info@hfwsolutions.com

- Contact us today >

Friction Stir Welding

Friction stir welding is a solid-state joining process that uses frictional heat. Using this method creates a high-strength, high-quality weld. Friction stir welding has many applications, including, but not limited to aerospace, shipbuilding, aircraft, construction and architecture, and automotive industries. Learn about friction stir welding >

BETTER

FASTER

CHEAPER

Advantages of Friction Stir Welding

- Provides significantly stronger joints than fusion welding or mechanical fastening

- Produces joints that will never leak....ever

- A solid state process leads to lower defects, distortion, and residual stress

- Cost effective - providing a dramatic increase in production efficiency

- Requires no filler material

- CNC controlled which allows for consistent results

- Allows for the joining of dissimilar alloys and high strength alloys more efficiently

- Environmentally friendly and safe

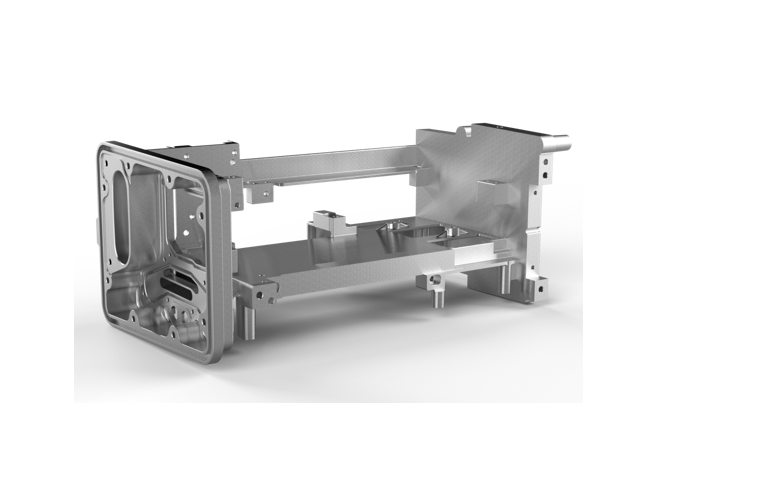

CNC Machining

HFW team members specialize in developing and producing high-volume production friction stir welded, machined, and fabricated products in virtually every alloy and joint group for our partners.

Expertise

HFW team members have developed friction stir welds in virtually every alloy and joint type for customers in:

- Passenger rail

- Aerospace & Space launch

- Agricultural/heavy equipment

- Automotive

- Marine

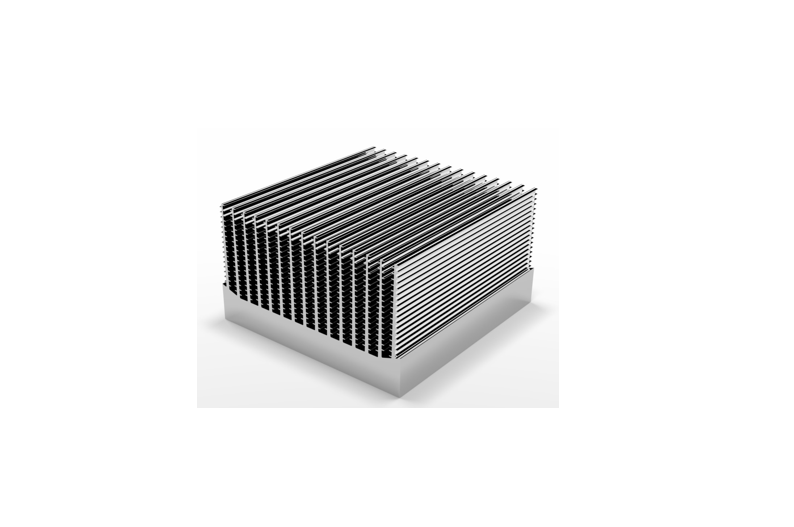

- Thermal Management

Featured Products

HFW’s friction stir welding and machining capabilities allow for a broad range of industries to be served and products to be made. HFW has years of experience making fully fabricated structures from large extrusions and is a leader in producing highly complex, small components from castings and plate. HFW has been a key service provider for the aerospace, architecture and construction, hybrid electric vehicle, marine, rail, thermal, and truck trailer industries for nearly a decade.

Resource Library

FUNDAMENTAL PROPERTIES OF FRICTION STIR WELDED AL 7136 INCLUDING EFFECTS OF POST-WELD ARTIFICIAL AGING

Recently, a new 7XXX series aluminum alloy designated 7136 has been developed by Universal Alloy Corporation (UAC) for aerospace applications. Base material properties of 7136 are compared to friction stir welded joint properties. Additionally an investigation into post-weld artificial aging and corrosion was conducted. The FSW joint properties and aging behavior of 7136 was also compared to 7075-T73 and some of the replacement alloys for 7075-T6 which have been identified by the Navy, specifically 7055-T74 and 7249-T76. Trends in the overall aging behavior of 7XXX series alloys, friction stir welded in the T7x condition are discussed. Preliminary results show that the corrosion resistance of 7XXX series alloys welded in the T7x condition can be significantly enhanced by the application of post-weld aging following FSW. Post-weld aging is also required in order to stabilize the microstructure in 7XXX series alloys, which would otherwise continue to naturally age indefinitely as indicated in the literature. Microhardness, electrical conductivity, tensile and exfoliation corrosion test results, as well as an assessment of the metallurgical characteristics, is presented.